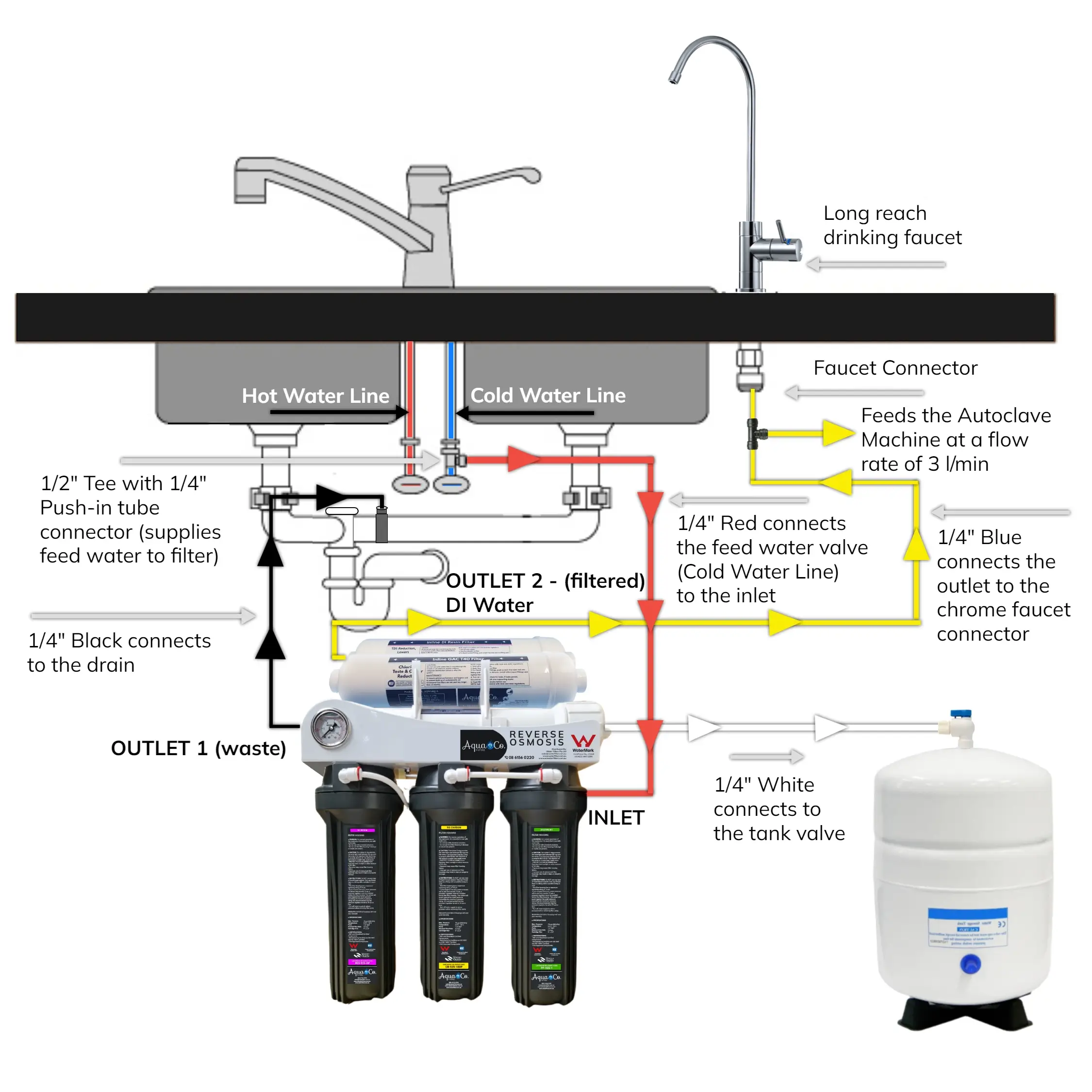

STAGE 1 PARTICLE FILTER

A sediment filter in the first stage which will capture sand, iron particles and suspended matter. This filter has 3 layers. The outer layer has 10 µm, the middle layer has 5 µm and the inner layer has 1 µm. This traps the dirt throughout the filter making for more efficient filtration.

STAGE 2 & 3 ACTIVATED CARBON FILTER

Stages 2 and 3 have a coconut shell activated carbon filter which through adsorption filtration. This filter will adsorb Chlorine and other disinfectants used in the scheme water supply. Also, will protect the main component in the filtration system, the reverse osmosis membrane.

STAGE 4 REVERSE OSMOSIS MEMBRANE – WATER SOFTENER

The reverse osmosis membrane is the third stage which captures all the calcium, salts, organic and inorganic molecules with the result being softened water.

Additionally, this prevents the accumulation of scale within the Autoclave Sterilizer protecting the machine from corrosion producing high purity steam during the sterilization process.

STAGE 5 & 6 ION EXCHANGE FILTERS

Stages 5 and 6 consist of ion exchange filters that further reduce the TDS (Total Dissolved Solids) from the water. The complete process as explained allows the water to have a TDS reading of Zero, ideal for the sterilization of medical equipment.

Reverse Osmosis Contaminant Removal List

Effectively Removes:

Aluminium

Copper Sulfate

Mercury

Sodium

Aluminium Chlorohydrates

Cryptosporidium & Giardia

Molybdenum

Sodium aluminates

Aluminium Sulfate

Cysts

Nickel

Sodium carbonate

Ammonia

Dioxins

Nitrates

Sodium Fluoride

Ammonium Sulfate

e. Coli Bacteria

Organic and inorganic substances Sodium fluorosilicate

Arsenic

Ferric Chloride

Organochloride pesticide Sodium hexametaphosphate

Bacteria

Fluorides

Organochlorides Sodium hydroxide (caustic soda)

Barium

Heavy Metals

Ozone Sodium hypochlorite

Bisphenol A (BPA)

Hexafluorosilicic acid

Per- and polyfluoroalkyl substances (PFAS)

Sodium silicate

Cadmnium

Human Pathogens

Poly aluminium silica sulfates Sodium tripolyphosphate

Calcium

Hydrocarbons

Polyacrylamides Sulfuric acid

Calcium Hypochlorite

Hydrochloric acid

Polyaluminium chlorides Taste & Odour

Calcium Oxide

Hydrofluorosilicic

Polychlorinated biphenyls (PCBs) Turbidity

Carbon activated Hydrogen Peroxide

Polydiallyldimethylammonium chlorides Viruses

Chloramines

Hydroxylated ferric sulfate

Potassium VolatileOrganic Compounds (VOCs)

Chlorine

Iron

Potassium permanganate Zinc

Chronium

Lead

Radium Zinc orthophosphate

Cobalt

Magnesium

Sediment, Dirt & Rust

Copper

Manganese

Selenium